Gas design for Revit

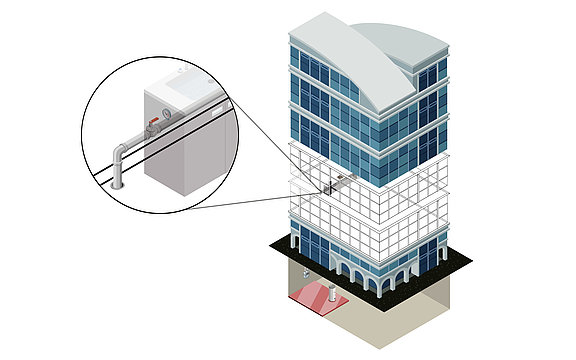

With the LINEAR solutions, a continuous workflow in gas design is guaranteed. From the design in early concept phases and the MEP model creation to the drawing of the gas consumer to the pipe network construction and calculation: Create your design quickly and efficiently with LINEAR for Revit.

The LINEAR workflow

Input:

Concept structure of the architecture with rooms, floors and functional areas

Output:

Located space requirements for technical rooms and pipeline corridors

Work steps:

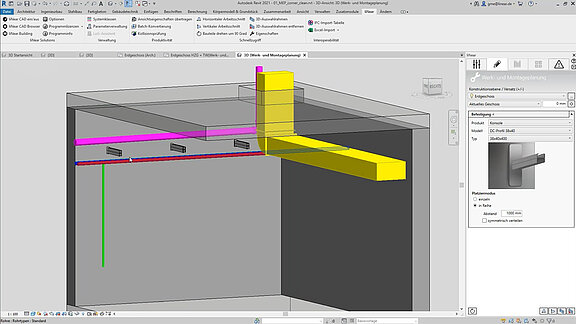

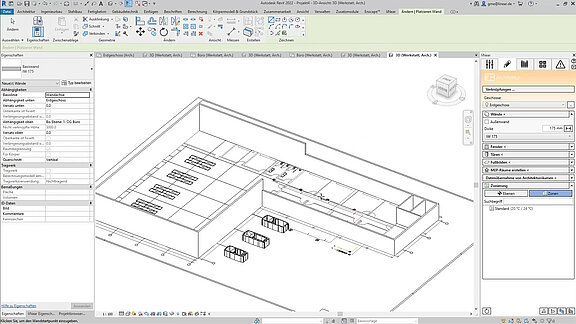

- Workflow for a collaborative early design phase planning

- Creation of a concept design on the basis of the requirements planning

- Conceptual space design (Provision for spaces)

- Localization and pre-dimensioning of technical equipment rooms

- Localization and pre-dimensioning of the pipeline corridors

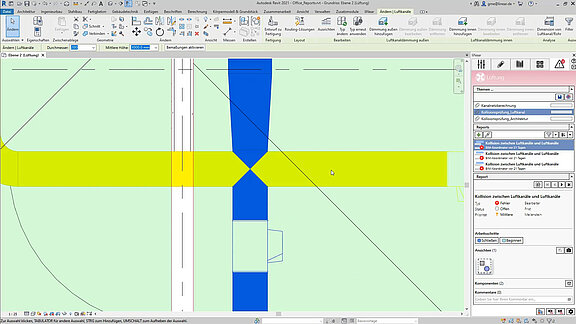

- Cross section editor for the pipeline corridor concept

- Generate pipe and duct elements from corridor concept

Input:

Architecture model or plan

Output:

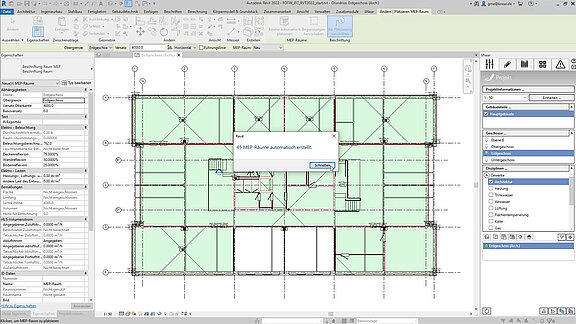

Model for further MEP design including levels, zones & MEP rooms

Work steps:

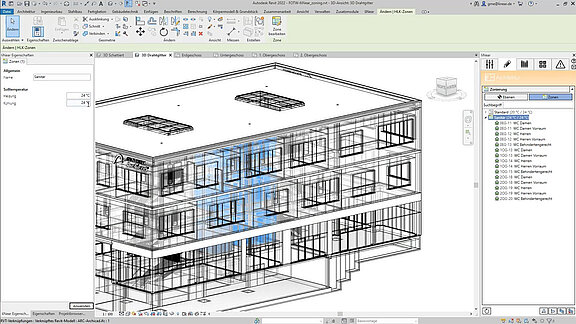

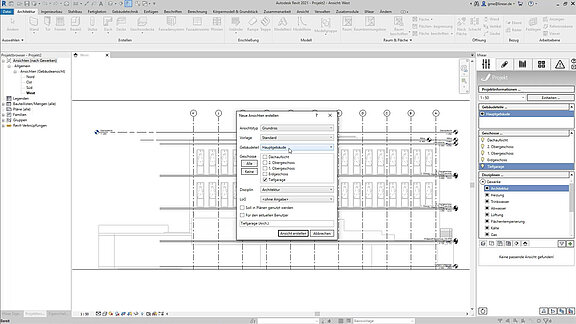

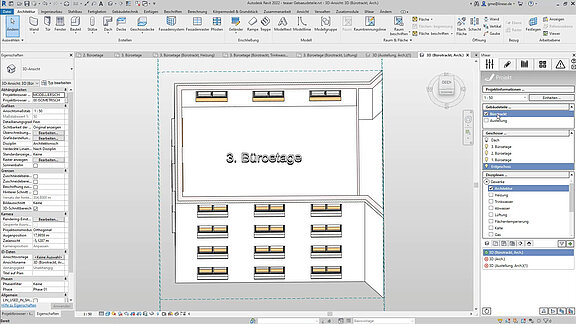

- Easy creation of the MEP model based on the architecture

- Enrichment of the model with relevant information

- Automatic creation of views and plans

- Parameter management for the assignment of parameters used in the project

- Optional for 2D templates: Simple rebuild of the building in 3D

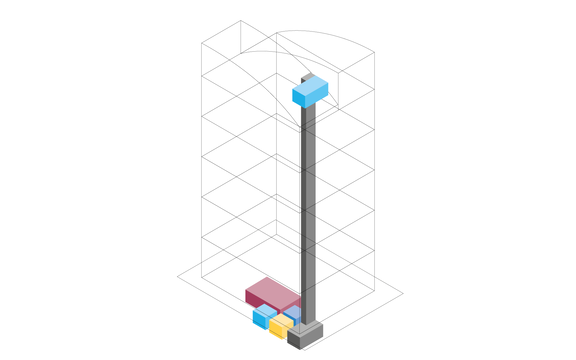

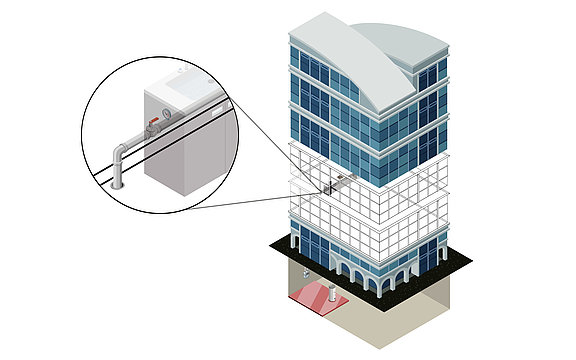

Input:

Model for the MEP design including levels, zones & MEP rooms

Output:

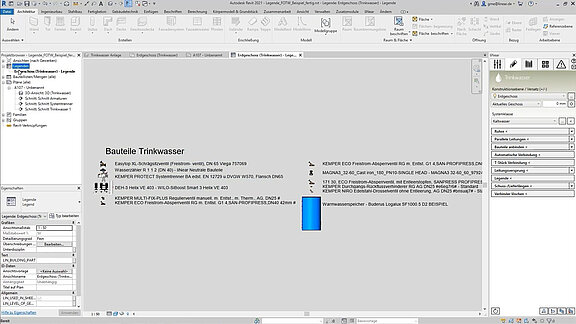

MEP model with placed gas components

Work steps:

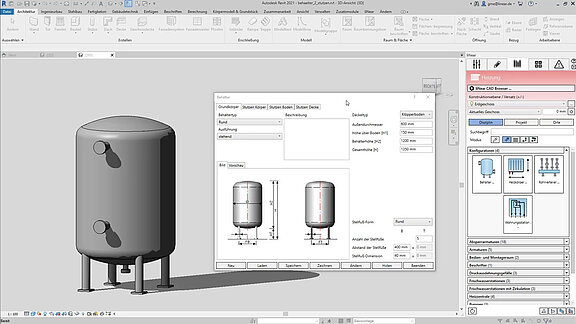

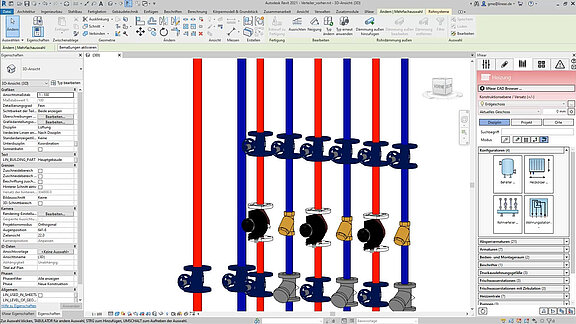

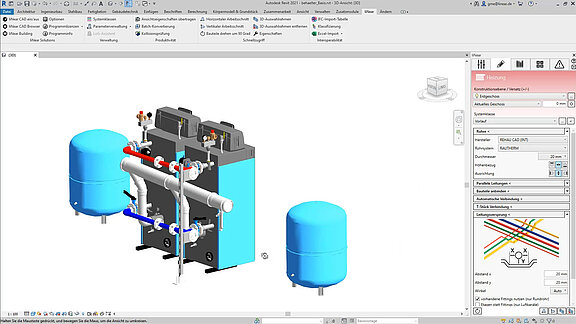

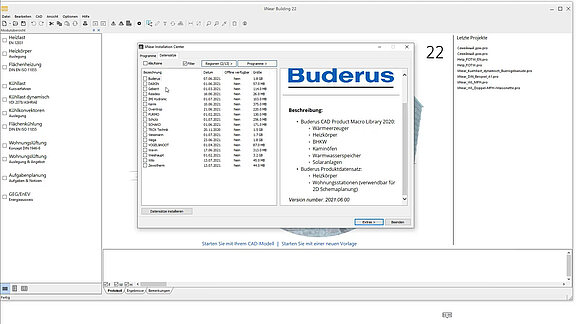

- Selection of gas consumers as neutral components or from the extensive manufacturer CAD libraries

- Easy placement in the model by specific drawing commands

- Integration of system components (e.g. house connections, gas flow monitors, meters, fittings)

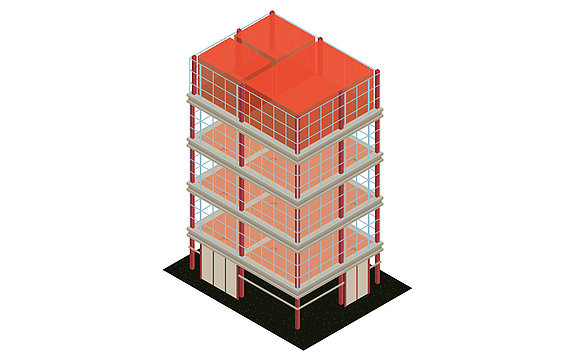

Input:

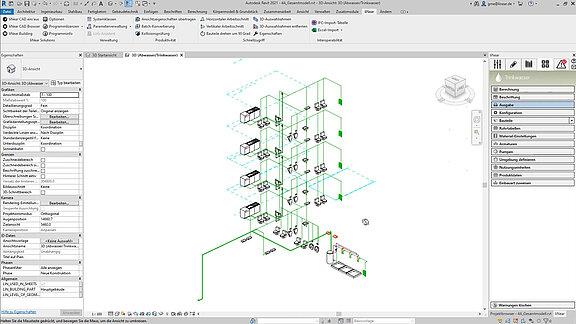

MEP model with placed gas components

Output:

MEP model with optimized systems as well as the finished void planning

Work steps:

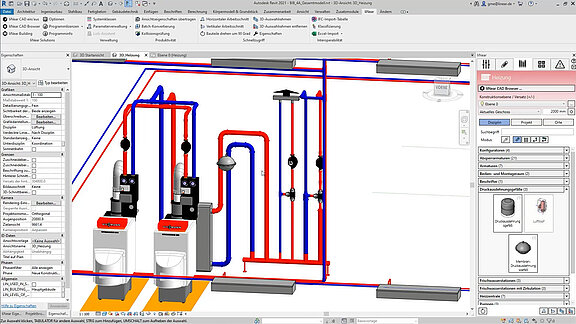

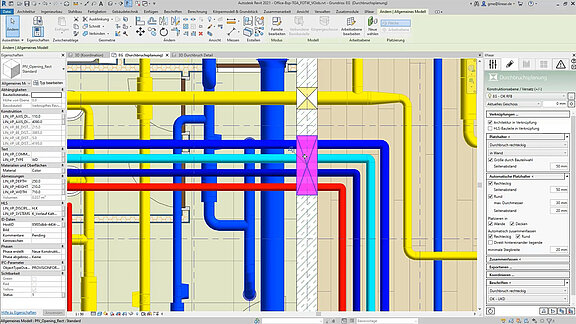

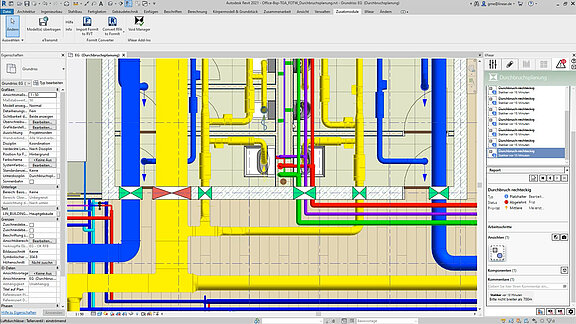

- Fast pipe network construction as a single pipe or as parallel pipes

- Automatic connection of all consumers

- Plant design neutral or with the help of extensive manufacturer CAD libraries

- Specification of calculation-relevant specifications (e.g. assignment of pipe materials, settings of valves, Gas flow monitor)

- Comparison of variants by using verified manufacturer data sets (e.g. pipe systems)

- Calculation of existing networks by fixing individual or all dimensions

- Redimensioning of the gas pipe network on the basis of the calculation

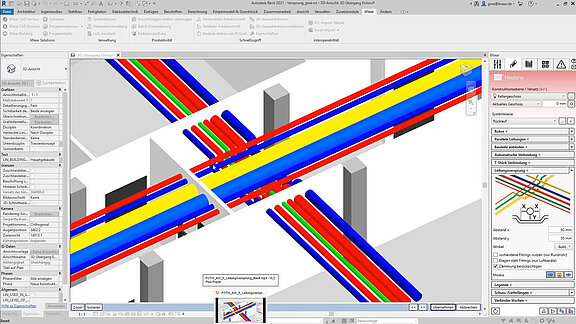

- Colored display of all results directly in the model (LINEAR data coloring)

- Void planning including coordination via BCF and IFC

Input:

Calculated and optimized gas pipe network

Output:

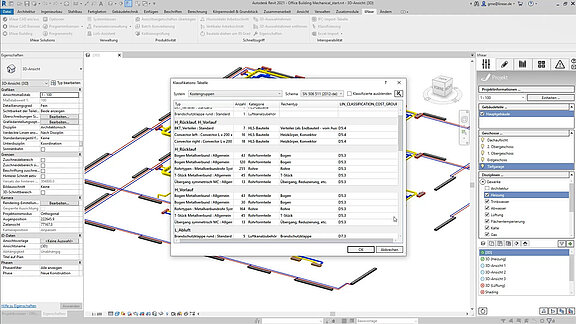

Final gas design including model for transfer to the coordination model and calculated results incl. material lists

Work steps:

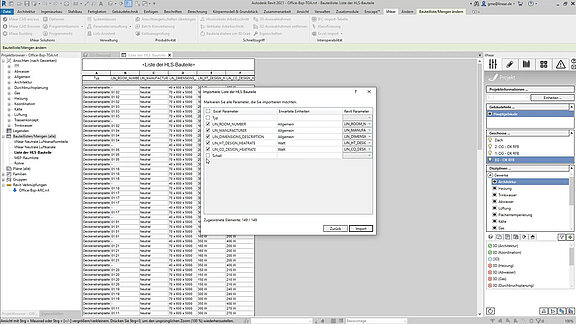

- Storage of all inputs and calculation results in the model

- Publication of selectable values as shared parameters

- Automatic labeling of the model

- Addition of own parameters and meta information

- Printout of the results in standardized forms

- Transfer of the results and the model in all relevant formats

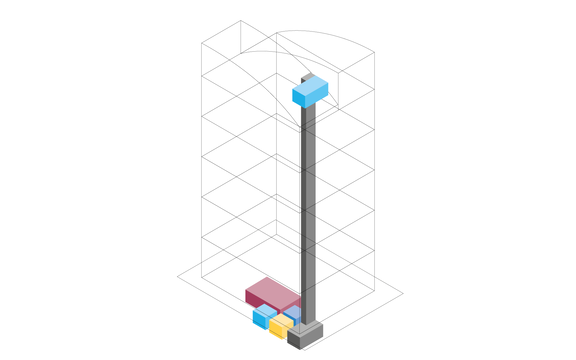

Input:

Concept structure of the architecture with rooms, floors and functional areas

Output:

Located space requirements for technical rooms and pipeline corridors

Arbeitsschritte:

- Workflow for a collaborative early design phase planning

- Creation of a concept design on the basis of the requirements planning

- Conceptual space design (Provision for spaces)

- Localization and pre-dimensioning of technical equipment rooms

- Localization and pre-dimensioning of the pipeline corridors

- Cross section editor for the pipeline corridor concept

- Generate pipe and duct elements from corridor concept

Input:

Architecture model or plan

Output:

Model for further MEP design including levels, zones & MEP rooms

Arbeitsschritte:

- Easy creation of the MEP model based on the architecture

- Enrichment of the model with relevant information

- Automatic creation of views and plans

- Parameter management for the assignment of parameters used in the project

- Optional for 2D templates: Simple rebuild of the building in 3D

Input:

Model for the MEP design including levels, zones & MEP rooms

Output:

MEP model with placed gas components

Arbeitsschritte:

- Selection of gas consumers as neutral components or from the extensive manufacturer CAD libraries

- Easy placement in the model by specific drawing commands

- Integration of system components (e.g. house connections, gas flow monitors, meters, fittings)

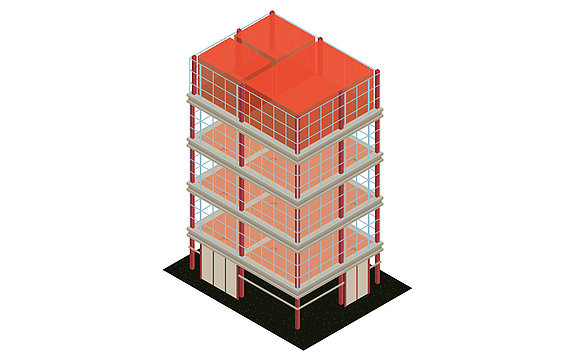

Input:

MEP model with placed gas components

Output:

MEP model with optimized systems as well as the finished void planning

Arbeitsschritte:

- Fast pipe network construction as a single pipe or as parallel pipes

- Automatic connection of all consumers

- Plant design neutral or with the help of extensive manufacturer CAD libraries

- Specification of calculation-relevant specifications (e.g. assignment of pipe materials, settings of valves, Gas flow monitor)

- Comparison of variants by using verified manufacturer data sets (e.g. pipe systems)

- Calculation of existing networks by fixing individual or all dimensions

- Redimensioning of the gas pipe network on the basis of the calculation

- Colored display of all results directly in the model (LINEAR data coloring)

- Void planning including coordination via BCF and IFC

Input:

Calculated and optimized gas pipe network

Output:

Final gas design including model for transfer to the coordination model and calculated results incl. material lists

Arbeitsschritte:

- Storage of all inputs and calculation results in the model

- Publication of selectable values as shared parameters

- Automatic labeling of the model

- Addition of own parameters and meta information

- Printout of the results in standardized forms

- Transfer of the results and the model in all relevant formats

Features

Construction Tools

- Piping command including system class determination

- Automatic connection of pipes, including necessary transitions (autorouting)

- Automatic T-piece connection

- Offset command for resolving collisions

- Extensive component libraries incl. meters, filters, pressure monitors, flow monitors, fittings and built-in parts

- Configurators for radiators, convectors, manifolds and tanks

- Design of parallel pipes/ducts

- Design tools for fixings, flanges, delivery lengths, etc.

- Legend function

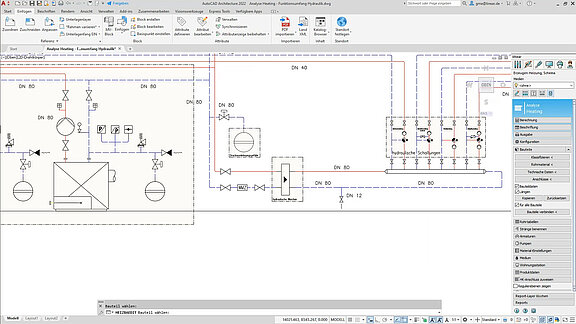

Pipe network calculation incl. redimensioning

- Automatic calculation and dimensioning of all components of the gas pipe network.

- Consideration of given gerneral conditions e.g. limit values for velocities and the pipe friction pressure gradient (R-value)

- Determination and comparison of variants of pipe materials and components incl. original manufacturer data sets with real product properties

- Calculation directly in the model incl. redimensioning

- Gas pipe network calculation according to TRGI 2018, TRGI 2008 /DVGW G600, DVGW G617, ÖVGW G11 and TRF 2012

- Calculation in every design phase directly in the model

- Calculation according to TRGI for plants with an operating pressure up to 100 mbar

- Calculation of industrial plants with operating pressures up to 5 bar

- Calculation with real product properties using data sets from leading manufacturers

- Input of material values (methane, butane, biogas)

- Gas xxcess flow valve can be dimesnioned automatically

- Interface for valve data sets, shut-off valves, differential pressure controllers, volume flow controllers, control valves, control valves and fixed resistors

- Alternative calculations according to Zanke, Prandtl Colebrook and Prandtl-Kármán

- Design of compressed air pipe networks possible

- Visualization of results using LINEAR Data Coloring (e.g. dimensions, materials, velocities, pressure losses, etc.)

Hydraulic balancing of complex systems

- Hydraulic calculations with transfer of performance data from family parameters

- Calculation of multiple systems in one model

- Determination also of networks with several control levels

- Consideration not onlyof the distribution networks, but also the generator part

View creator and view control

- View creation assistant for 3D views, floor plans, ceiling plans and area plans

- Quick 3D selection box command

- Quick working section commands

- Automatic sorting and assignment of views

- Suggestions for best suitable views

- Automatic LOG assignement to views

- View filter

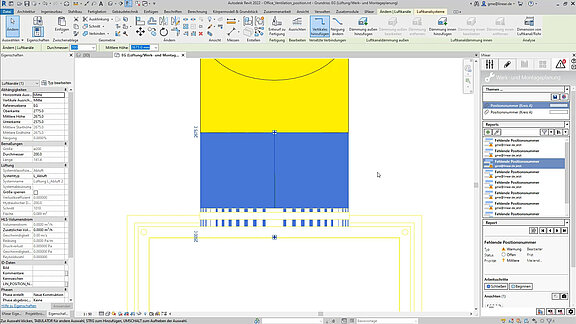

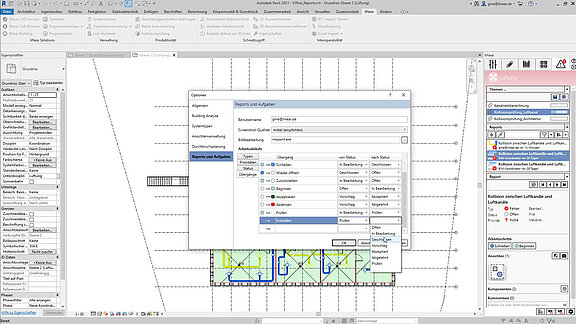

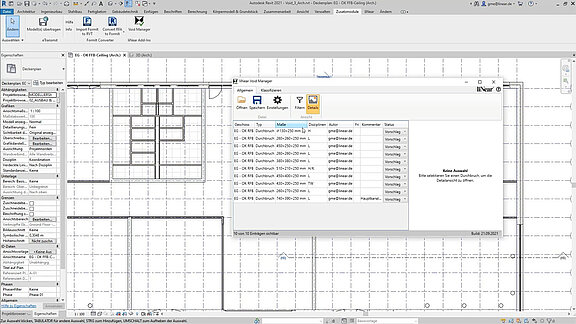

Task management

- Assigning of responsibilities for automatic (e.g. from the calculations) or manually created tasks

- Set of deadlines and priorities for tasks

- Status tracking of tasks

- Definition of given workflows for the resolution of tasks

- Adding of Screenshots, comments, positions to tasks

- Sharing and assignment of tasks to participants via BCF

Automatic labeling

- Automatic label-selection according to the component class

- Free configuration of label content

- Addition of custom parameters and meta information

- Automatic dimensioning

Family and library management

- Providing of all necessary components for your project centrally

- Components or configurators suitable for the active discipline

- Filtered by active discipline, used in project and locations (local or folder in the network)

- Sorted in component groups for quick orientation

- Multiple placing comands for families (place, replace, replace all, place on grid)

- Integration of own family libraries

- Intelligent search function

- Pick and place again of a component in the model

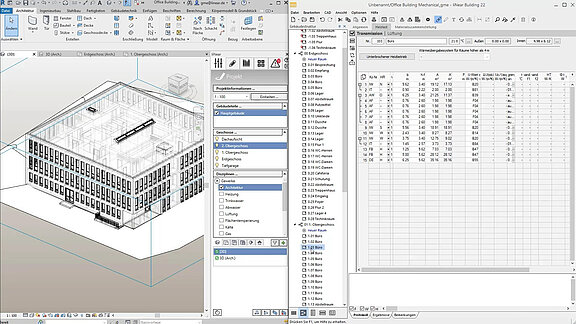

Storey table

- Automatic import of storeys from the architectural model

- Control of the storey in the Construction level / offset (+/-) section

- Easy Creation of storeys and work levels

- Separate storey table for mutliple building parts (e.g. for split levels)

Industry components via CAD Browser

- Extensive CAD libraries with approved components of our wide range of industry partner

- More than 6 billion possible components and component combinations

- Direct placement of original manufacturer components into your model

- Multiple placing modes (place, insert, replace)

- Configurators for complex component combinations (e.g. cascade systems)

- Including technical and commercial data (e.g. article numbers and packaging units)

- Detection and consideration in the network calculations

Interoperability and collaboration

- IFC Import configuration

- Classification of IFC or other structures

- Excel import and export

- Reports and tasks manager for BCF exchange (incl. chat function)

- Common topics and status tracking for BCF exchange

Collision checker

- Detection and display of collisions of any kind within a project or between several projects

- Collision check between Architecture and all disciplines

- Collision check between two discipline or one discipline with the architecture

- Collision check between single or multiple categories (e.g. walls and pipes)

- Collision check between single or multiple systems (e.g. Gas and exhaust air)

- Automatic creation of tasks for each collision in the Report and Task Tab

- Saving and Loading of predefined configurations

Collaboration in early design phases

- Workflow for a collaborative early design phase planning

- Dimensioning of equipment rooms

- Conceptual space design (Provision for spaces)

- Cross section editor for the pipeline corridor concept

- Redimensioning of provisions for space

- Generate pipe and duct elements from corridor concept

Parameter manager and classification tool

- Assigning of liNear parameters to your own shared parameters in a project-dependent mapping table

- Search and filter functions for mapping or overwrite of parameters

- Loading and Saving of predefined project standards

- Assignment of classification parameter to components and model elements to fill it with values

- Structure the classification of component groups in the IFC export

- Classification components related to cost groups for precise cost estimations

Void planning

- Manual placement

- Automatic placement

- Across referenced files

- BCF-Export (optional incl. IFC) for collaboration

- BCF-import for status alignment

Visibility control

- One click visibility control for building parts

- One click visibility control for storeys

- One click visibility control for disciplines

- One click visibility control for component groups (e.g. systems, insulations, etc.)

Language selection for interface and printouts

We provide you with no less than seven languages, which you can use and combine as you wish, either as the interface language or the print language. In this way, it is possible to design in one language and print in another. This is a great advantage, especially for international projects, as time-consuming translations are no longer necessary. There are no additional costs for the language packages.

The following languages are currently supported:

- German

- English

- French

- Dutch

- Russian

- Turkish

- Italian

Parts list with article numbers

- Clear and comprehensible calculation results as well as complete bills of materials

- Detailed parts lists with part numbers and material checks

- Bills of materials in various output formats (Windows printout, Excel, text, UGS, GAEB, ASD)

Management of system class properties and quick selection

- Central management of system class properties

- Intuitive system table

- Quick selection of the system

MEP model creation (Architecture)

- Automatic or manual MEP room creation

- Zoning tool

- Architectural functions for easy post-modeling of 2D architectural plans

Supported standards

LINEAR has always stood for standard-compliant calculation and design. It is both our concern to always offer the latest standards and to constantly expand the range nationally and internationally. An up-to-date overview of all supported standards can be found in our knowledge base at [LINK].