The municipality of Fuchstal in Bavaria wants to be energy self-sufficient by 2030. Due to its achievements to date, it received the award for Energy Community of the Month from the Agency for Renewable Energies (AEE) in May 2022. Thanks to the consistent expansion of renewable energies, the municipality already covers its own electricity requirements with the renewable plants installed in the municipality's area. The coupling of electricity and heating sectors significantly advances the heating transition and economic efficiency.

The municipality generates around 40 million kilowatt hours (kWh) of sustainable electricity every year, which even exceeds the consumption of all residents of around 30 million kWh per year. The council has decided to use a combination of biogas, solar and wind energy. Decisive investments have already been made in a municipal wind farm and in an open-space solar plant in the past.

"Municipal investments in a decentralized, sustainable energy supply are not really only an end in themselves, but secure ecological foundations as well as prosperity and local energy security, especially in smaller municipalities," confirms AEE Managing Director Robert Brandt.

Reasonable coupling of sectors as an overall concept

The combination of the sustainable energy sources mentioned above enables maximum flexibility. By linking individual energy generators and by creating storage options for electricity and heat, the operation of all components is optimized both economically and energetically.

This way, the waste heat from the biogas plant, which would go unused on warm days, can be stored, and fed into the municipal heating network. The electricity generated by wind turbines and the municipality's own photovoltaic systems is used in a similar way. In times of low demand, when it would be uneconomical to feed the generated electricity into the network, Fuchstal opts for a power-to-heat system and a 5.8 MW battery storage unit. The electricity stored in the battery can then be fed into the network when electricity prices improve, and the surplus can be used in form of heat.

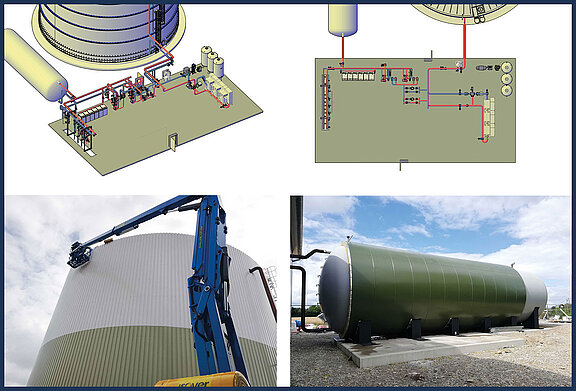

To make this possible, the city built the new control center for the municipal energy and heat supply on an area the size of a soccer pitch. It consists of a battery storage system, a power-to-heat module with an output of 4.7 MW, a pendulum storage tank with a volume of 200 m³ and a huge 5,000 m³ heat buffer storage tank with a capacity of approx. 150 MWh and corresponding control technology. The project received almost six million Euros of federal funding and clearly demonstrates the feasibility of sensible sector coupling as a building block for the heating transition.

The plant now enables the city to use electricity from the public network cost-effectively in times of power surplus while avoiding the curtailment of its renewable energy systems. The network is thus less strained and generated electricity can be stored and used later.

Up to 450 properties can thus be supplied with sustainable heat via the comprehensive heating network. The project "Energy Future Fuchstal" aims to turn the community into a self-sufficient energy supplier in the long run. The local heating network plays a decisive role in this. The project has already attracted attention beyond community borders. Representatives from various cities and communities both in Germany and abroad are traveling to Bavaria to see the project and to take the ideas back to their own communities.

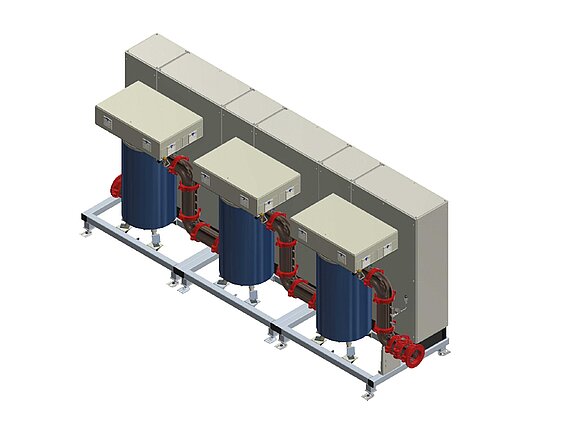

Power-to-heat plant with buffer storage including system engineering

The core of the energy concept is the power-to-heat plant in combination with the 5,000 m3 buffer storage tank. The plant was designed and installed by the company Hans von Bebber from Straelen. The LINEAR software solutions were used for designing the entire plant.

The company relied on 3D construction with LINEAR Design 3D Pipe&Power. Managing Director Thomas Paes comments: "For us, consistent 3D design not only offers advantages during the project, but it is also a powerful tool when it comes to securing new contracts. Even before the contract is issued, we can convince our customers of the concept and make the design immediately tangible. Experience has shown that these early models already correspond to around 80 to 90 % of the final design which means we can deliver results very quickly once the contract has been signed. This also often means that we can already provide the architect with specifications for the cubature of the technical rooms and information on the required foundations at an early stage. We are involved right from the start and can communicate the requirements for the smooth implementation of our design well ahead of time. For us, there no longer is any alternative to end-to-end 3D design with LINEAR."

In addition to the actual construction, Hans van Bebber also supplies the associated calculations and uses 3D models already in early design stages. The models provide all required information to deliver manifolds and systems to the construction site almost completely assembled and ready to be installed on the basis of the 3D model.

A best-practice pilot project

The project implemented in Fuchstal impressively demonstrates the importance that sector coupling can play in the energy and heating transition and that the systems are not only feasible but can also be economically viable with appropriate state funding, even in such a pioneering stage. If politicians set the right course here, many of these systems could play a decisive role in overcoming the challenges on the way to a sustainable energy industry.

OUTSTANDING CRAFTSMANSHIP QUALITY FOR OVER 50 YEARS

Hans van Bebber is a family business founded in 1965 in Straelen in the Lower Rhine region. The founder, Hans van Bebber, handed over the business to his eldest grandson Thomas Paes in 2007 at the age of 74. Today, around 15 technicians, assistants, and apprentices work for Hans van Bebber.

The company stands for expertise in designing and implementation of flexibilized biogas and CHP heating plants with large buffer storage tanks. In addition to energy consulting and the design of new plants, the company also offers the optimization of existing plants.

Sources: